Contents

What is Brick masonry? Types of Bricks

Brick Masonry Definition

Brick Masonry Definition; It is a very highly durable form of construction. It is constructed by placing a brick in mortar in such a systematic way to construct a solid structure, that withstands applied burdens. There are many different types of bricks and mortars, which are used in brick masonry work.

The bond between two bricks in brick masonry, which adheres bricks together. The joints between brick filled with suitable mortar. Precaution to be taken while mixing and placing mortar in Brick joints. However, it is greatly affected by the quality and durability of the Brick masonry.

Types of Brick Masonry Work

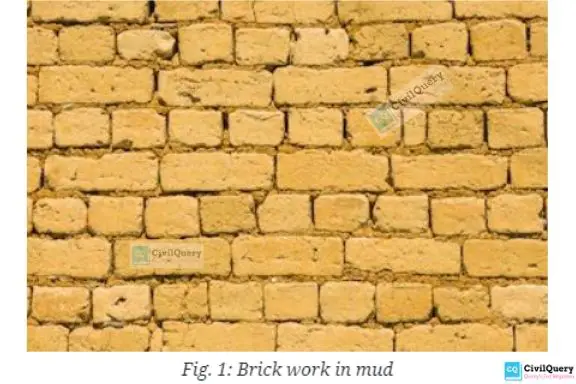

Brick Masonry work in Mud

In this type of Masonry work mortar is made from Mud and mixed with water.

Mud is used to fill up brick’s joints in masonry work.

Maximum thickness of mortar joint is 12mm in this type of masonry work.

This type of Brick masonry work done for the construction of wall with maximum height of 4 M.

This type of masonry work is very cost effective.

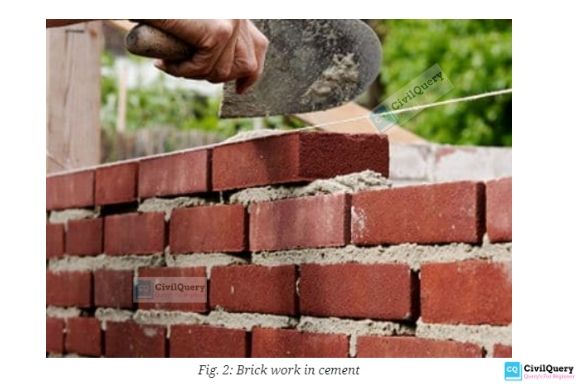

Brick Masonry work in Cement.

This type of Brick masonry work by laying bricks in Cement Mortar rather than in Mud Mortar.

Cement Mortar is used to fill joints between Bricks in Masonry work.

Thickness of Cement mortar is used Fill Joints in Masonry work is Maximum 12mm

There are three major Classes of brick masonry work in cement, which are explained in below Table

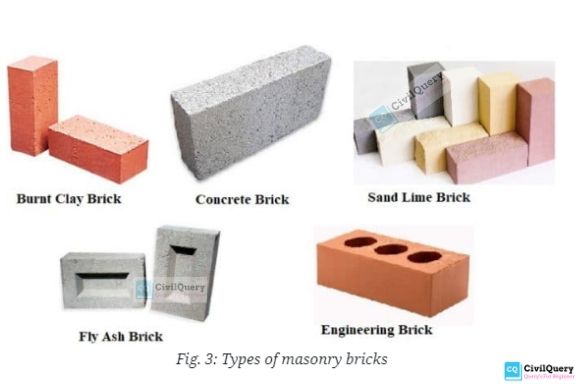

Types of Bricks

There are several Different types of Bricks used in Building Construction. Types of bricks are as follow.

- Common Burnt Clay Bricks

- Concrete bricks

- Sand Lime Bricks (Calcium silicate bricks)

- Fly ash Clay Bricks

- Engineering bricks

- There are several different types include bullnose, channel, Coping, Cownose, and Hollow bricks.

1. Common Burnt Clay Bricks

Clay bricks are formed in a mould (the soft mud method), or more frequently in commercial mass production by extruding clay through a die and then wire-cutting them to the desired size (the stiff mud process).

The shaped clay is then dried and fired either by burning in a kiln or sometimes, in warm and sunny countries, by sun-drying to achieve the final, desired strength.

Read Also: Clay bricks or AAC blocks, which one is better in strength and economy?

Read Also: Why Cracks occurs in Plaster?

The action of heat gives rise to a sintering process that causes the clay particles to fuse and thus develops extremely strong ceramic bonds in the burnt clay bodies. Such bonds are highly stable.

As a result, bricks can withstand severe weathering actions and are inert to almost all normal chemical attacks.

2. Concrete Bricks

Concrete brick is a Form of cement and aggregate, usually sand, formed in molds and cured. There are Certain mineral colors are added to produce a concrete brick resembling clay.

3. Sand Lime Bricks (Calcium silicate bricks)

Sand Lime Brick is Brick, that uses Lime instead of Cement. It usually looks White brick made of Lime and Sand, cast in Moulds and Cured.

4. Fly ash Bricks

Fly ash Bricks are well improved high-quality bricks, which are used for the construction of brick masonry structures. They are also used as a replacement of normal Clay bricks and it has better properties than it.

5. Engineering Bricks

Engineering bricks are Clay bricks, which fired at a higher temperature than normal clay brick. It is very much resistant to water and pressure and, it is also used to support lintels above windows and doorways.

Materials and Equipment used in Brick Masonry Work

Trowels

The use of Trowel is to Mortar from board to place and spread mortar on the set-of bricks. It comes in Triangular Shape. It comes with a size vary and can reach up to 11 inches in length and 8 inches in width. Most of the mason prefer using short and wide trowels. So, they do not have to put excessive stress on the wrist.

Chisel

A Chisel is used to cut bricks into the required size. Chisel comes with the size ranging from 21/2 Inches to 41/2 Inches.

Hammer

The Hammer used in brick masonry, which has a square face on one end for Breaking brick, on other ends it has a sharp edge for cutting brick. This tool often used to split hard bricks.

Jointer

This Jointer tool is used to make mortar joints in brick masonry work. Jointer comes with three different shapes; Flat, rounded and pointed.

Squares

The Squares are used for constructing and measuring right angles and corner layout in Structure. They are usually made up of durable material for durability (Metal)

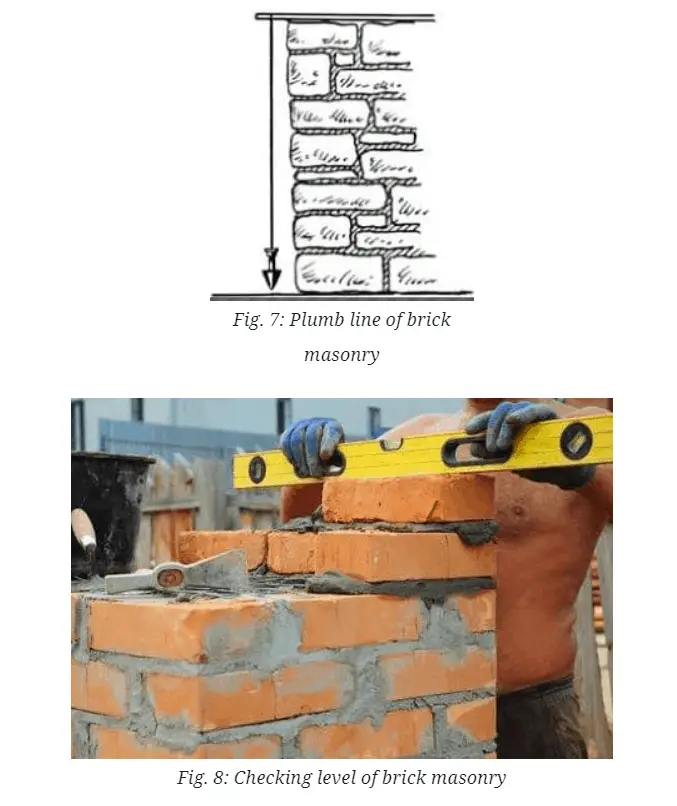

Mason’s Level

The Mason’s level is used, when establishing vertical or Plumb lines and horizontal or level lines. They are generally made up of Wood and metal or combination of both. They equipped with either single or double vials. This tool is preferred by most the masons since they can use to measure vertical and horizontal measurement.

Straight edge

These tool act as extensor to mason’s level. They are used, when levels are shorter than the area that needs to be measured. A middle section of the top of the straightedge must be horizontally parallel to the bottom section. Common Widths of these tool range from 11/8 Inches to 11/2 Inches. These tools can be as long as 16 feet.

Preparation Before Brick Masonry Work

Brick Masonry Procedure

- At Starting, Mix the Cement Mortar with water and blend it until smooth mortar is produced.

- After mixing the mortar thoroughly, using trowel place the mortar evenly on foundation line (Max 25mm Thickness and 1 brick wide recommended)

- After that, Lay the first layer of the bricks on the Mortar. Start with second brick, apply the mortar on the head joint end of each brick, thereafter shove the bricks into place firmly, so that mortar is squeezed out from all the joints of bricks.

- Use a level to examine the course for correct height and ensure the bricks are in plumb and level.

- Place the second mortar line alongside the first layer of bricks, then begin laying the second Bricklayer.

- Use the 2 half bricks to begin the second layer, to ensure that the first to a course are staggered for structural purpose.

- To complete the second layer of bricks, lay the three header layer bricks and make sure that they are in level and Plumb.

- Then the third and fifth course consists of stretchers similar to the first course. Then the fourth course begins with a single header followed by stretchers. Make sure you use the level to ensure the bricks laid is true on each course. Lastly, this procedure of bricklaying is continued until the target height is reached.

Point to be observed in Supervising Brick Masonry work

Following points to be observed during the Brick Masonry Work.

- Ensure the quality of Bricks

- Make sure that bricks courses are perfectly horizontal

- The verticality of the wall should be checked frequently using Plum-bob.

- Whenever work is stopped at the end of the day, the brick masonry work should be left with a toothed end

- Wall with a height of more than 1.5 m should not be allowed in one day.

- Brick masonry work should be cured continuously for 2 days.

- Add a face joint to a depth of 12 mm to 20 mm, so as to be used as a key for plastering or pointing.

- The thickness of a mortar joint shell is 10 mm to 12 mm both horizontally and vertically.

I was looking for types of bond in brick masonry. Well if you have any information regarding to types of bond kindly let me know

We value your comment and time, soon we will revert back to you on information regarding types of bond in brick work

Brick masonry is one of the most effective, readily used and the most durable form of construction, it is done through placing bricks within the mortar in a systematic manner in order to construct a solid mass capable of withstanding exerted loads.

Masonry cement is the mixture of portland cement, ground limestone and hydraulic cement coupled with a water repellent additive, and masonry cement is primarily used for mortar, due to the fact that it contains air entertainer which improves the workability of the structure and makes it frost resistance after hydration. However, the quantity of cement to be included is an essential element to be considered, therefore, it is recommended that you hire professional masonry contractor to perform the job for you.

Some advantages of brick masonry includes:

Bricks are light weight, and are easier to handle

Bricks are easily available and their costs of transportation is also quite less, comparatively stones have to be bought from queries which are located far away from the city

All types of mortar can be used for brick masonry which is certainly not the case when stones are being used

Thinner walls can be constructed using bricks, while this is something that can not be achieved via stones

Some of the most frequently types of bricks used for construction include; burnt clay bricks, concrete bricks, sand lime bricks, fly ash bricks and Unburnt Clay bricks.

Such a great information.. Keep it up

Thank You

I read an article, its amazing

Amazing article. very useful

As a stonemasonry company, this catches my eyes: “Point to be observed in Supervising Brick Masonry work.” However, the main point that I want to contribute, which was I always advise to my clients is to use and choose bricks of extraordinary quality with uniform color, well blaze but with exact shape and size. In doing so, the end results will long-lasting and durable.

Really helpful infromation sir

Thank you for teaching us all about masonry. I am new to the masonry business and I need all the help that I can get. I learned a lot today. I appreciate your informative content. Cheers to a more successful year of 2021! Best regards from our Washington DC masonry contractor.