Contents

What is Lightweight Concrete?

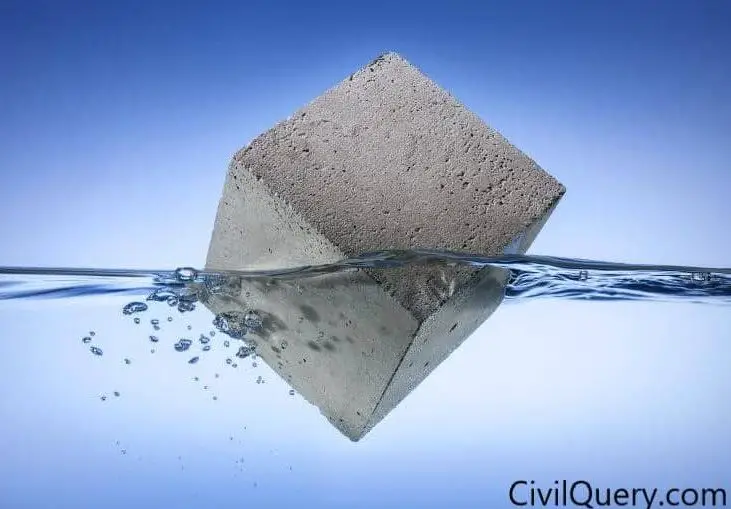

Weight is the bane of most construction materials and this is particularly true for concrete (density ∼2400 kg/m3 ). Fortunately, lower density concrete can be made using lightweight aggregates that have within their mass an array of vesicules or air voids that render these aggregates of significantly lower density than normal weight aggregates.

When these lower density aggregates are incorporated in a concrete mixture they can produce a structural grade concrete with a density of about 1850 kg/m3. In addition to the very obvious reduction in mass, the other advantages that lightweight concrete can provide include increased thermal insulation, extended moist curing and increased durability.

Lightweight aggregate concrete

As the name suggests lightweight aggregate concrete there are a lot of ingredients present in this concrete mix one of these is very important in aggregate.

Now in this, we are going to have a look at two types of aggregate they are natural and artificial aggregate.

Initially, we will see towards the coarse aggregate because it plays a vital role as far as the compressive strength of concrete is concerned.

So which type of aggregate can be included in the type of concrete.

The aggregates weigh less than 1000 kg/m3 are considered as light concrete. But now the question arrives why the aggregate is light in weight.

As mentioned above there are two types of aggregate natural and artificial. So now we will have a look at how many natural types of aggregate which are present and what are they.

Following are the type of aggregates which are used to prepare lightweight concrete.

- Pumice

- Diatomite

- Scoria

- Volcanic Cinders

- Silica Sand

- Gravel and Crushed Stone

- Volcanic Tuff

- Volcanic Slag

- Saw Dust

1. Pumice

These are the rock from the volcanic origin and these are the widely used and one of the oldest among the aggregates. These aggregates are not only light but these are strong enough and performs very well. These are light in color nearly white and even has a texture of interconnected cells which make them stronger one even though they are light in weight. Pumice aggregate is to be mined then it is to be washed then it can be used. It has high silica and alkali content and low in calcium and magnesium content.

2. Silica Sand

Silica sand which is suitable for ordinary concrete can be chosen but it should not contain clay or any organic content because when it comes in contact of water it imports the growth in it which will reduce the bond strength between the aggregates and this silt content should be less than 6%. All lightweight concrete like no fines and graded are mainly made of silica sand.

3. Gravel & Crushed Stone

As we all know the gravel are the small pieces of stone which we see around us and crushed stone are those which are crushed to a certain limit or till the required particular size is reached. Any gravel or stones fulfilling the required standards are suitable for no- fine concrete as these are very naturally occurring material so it should be thoroughly clean before using them. Among these two crushed stone is more preferable as it has a higher surface area and other higher properties it performs better as strength mainly depends on bond development crushed stone is more superior.

4. Volcanic Tuffs

Tuff is a type of volcanic fermented lava rock it can be said that it is a derivative of a volcano. This rock is made out of volcanic ash which is then erupted through a vent during a volcanic eruption. So following the eruption and after the consolidation, this ash is consolidated to form a rock this is a soft rock due to the pores which are the result of gas bubbles generated due to Rapid cooling and hardening of lava. When Lava comes out initially it is very hot but after a certain period of time it starts cooling and it solidifies. This cooling and solidifying process lead to bubbles formation. So the pores are the result of these bubbles. If you see the structure or texture of the tuffs it can be seen as Amorphous in nature, Vitreous in a structure that means they are glossy and smooth and they are chemically unbalanced. The pore properties vary from 10 to 60%. These tuffs are classified as Rhyolite, Dacite, Andesite, and Trap Tufts.

6. Volcanic Slag

It is also a derivative of volcano lava. It is vitreous but more crystallized slag-like material. The other features of volcanic slag are that it has high portions of ferrous oxide, lime and organic oxide, low in alkali content. Sulfur and sulfate content will not exceed 10.5% and 1% respectively.

7. Diatomite

It is another derivative of silica it is in a hydrated form which is amorphous in nature, they are derived from the remains of microscopic aquatic plants which are also known as diatoms or kieselguhr. The deposits of these aquatic plants are found beneath the ocean floor so during the continent formation these things came out. These are used as the workability agent and it has also got very good pozzolanic material. So it has the cementitious property and also the workability property too. Which is very good for the design engineer and site engineer because they are looking towards the workability and consistency so they can impart it. But the only problem with diatomite is that is not widely available in nature these are sintered in roller kilns to produce lightweight aggregate.

7. Scoria

These are also the aggregates with a volcanic origin. If we take a look at their structure it has larger, irregularly shaped cells which are not connected with each other. If we compare with tuffs they are connected with each other but scoria is not connected with each other because of which it is slightly weaker than the pumice.

8. Saw Dust

It is the substance that we get from the sawmills as a waste material. So it is used as a lightweight aggregate in floors and precast products, in jointless floor and roof tiling. When it is mixed with the cement then it adversely affects the setting and hardening time of the cement. Due to the presence of the tannins and soluble carbohydrates. But this problem can be solved by adding calcium carbohydrate by 5% by weight of cement. It is also observed that by mixing sawdust with cement it leads to the higher amount of shrinkage and moisture movement so it cannot be used where the places where the structure demands efficiency but in places like flooring or some architectural precast products it can be used. It is very cheap as it is a waste so it is used generally to wear cost-cutting is to be done.

Autoclaved Aerated Concrete

It is also known as AAC or Aircrete. It is a green precast building material in the global market for over 70 years. AAC produced in around hundreds of plants around the world and it is extensively used in residential, commercial and industrial construction. Autoclaved aerated concrete is eco-friendly building material made from natural raw material such as sand, fly ash, cement, lime, gypsum and aluminum powder. This mix creates aerated and lightweight concrete with strong structural properties. The unique characteristics of an AAC outperform traditional building material. The main advantages of an AAC include lightweight, excellent thermal insulation, fireproof, load-bearing capacity, fast and easy installation. Modern AAC plants with their aircraft technology are able to produce a wide variety of products including blocks, wall panels, partition panel floor and roof panel lintels, and thin fasard panels. AAC panels offer a range of new possibilities of product applications beyond an AAC block. In panel based building system installation of prefabricated elements is fast and easy as a result the total time and labor are reduced in construction.

Types of lightweight concrete based on Density and Strength.

Lightweight Concrete can be classified as:-

- Low-density concrete.

- Moderate strength concrete.

- Structural lightweight concrete.

1. Low-density concrete

These low density concretes are employing chiefly for insulation purposes. It shows very good properties of self-compacting. It has low unit weight, seldom exceeding 800kg/m3. Heat insulation values are high. But compressive strength is low, it varies from about 0.69 to 6.89 N/mm2.

2. Moderate density concrete

These type of concrete falls in between low density & structural concrete that means a value is intermediate. The use of these concrete requires a fair degree of compressive strength. This type of concrete can be used as a fill concrete like any were backfill is to be done it can be used. Its compressive strength approximately varies between 6.89 to 17.24 N/mm2.

3. Structural lightweight concrete

Structural lightweight concrete’s unit weight is considerably greater than those of low-density concrete. Insulation efficiency is lower. Most structural lightweight concrete is capable of producing concrete with compressive strength in excess of 34.47 N/mm2.

Advantages of lightweight concrete

- The density of the concrete is about 1840 Kg/m3 & density of ordinary concrete is 2400 kg/m3. This concrete is very lighter in weight as compared to ordinary concrete. Because of less weight, it requires less manpower, so it makes transportation economical.

- It has a very good property of insulation against sound and temperature. It also has a lower thermal expansion than ordinary concrete.

- Lightweight concrete reduces the dead load in structure. So, automatically it makes structure economical in all aspects.

- For the making of lightweight concrete, we can use industrial waste which is suitable and easily available.

Disadvantages of lightweight concrete

- Lightweight concrete is weak in the protection of reinforcement from corrosion. There are more chances of corrosion of steel than ordinary concrete. So, will have to take care of this.

Like, we will have to provide more cover to steel in case of lightweight concrete than ordinary concrete.

- The compressive strength of the lightweight concrete totally depends upon the type of aggregate we will use, it depends upon what cement content we have added and its compressive strength varies rapidly with water cement ratio.

- Because of different shapes and size of aggregate, this concrete is difficult to handling, placing and finishing.

- It takes more time to mix properly as compared to ordinary concrete.

Use of lightweight concrete

Many studies have proved that lightweight concrete gives same results like ordinary concrete. We can use this concrete in any type of structure with special care. It reduces dead eight of the structure. So it helps reduce the size of columns, beams, and footings also a percentage of reinforcement in structure. Lightweight concrete makes the structure very economical.

We can use lightweight concrete in a precast structure where transportation of precast members is very difficult also in bridge construction where we need high strength with light weight member’s in that case High strength lightweight concrete (HSLWC) is necessary.

AAC Block is also one of the types of lightweight concrete. This autoclaved block has a density range between 600-800 kg/m3 where clay brick has density 1900 kg/m3 with nearly same compressive strength.

Thank you